Making a strongback for mounting the forms

A strongback (the spinal cord) for mounting the forms is very important

and presents several challenges. It's difficult to find a straight

piece of 2x4 that is actually near 5 meters long.

Analysing the alternatives, I found the following options:

- 2x4's which are not too straight, and no garantee they'll keep

the actual form for a reasonable time. But economical!

- Nice and straight 2x4 beams of what is called 'compensated'

wood (actually selected and laminated), of good quality, but

quite expensive.

- Build a custom strongback using phenolic laminated wood.

- Use a metallic beam, but this presents problems for fixing the

the forms.

I finally decided to use the 'custom' strongback option, which came

out as costing about half of the laminated wood alternative. I selected

15 mm plywood. This alternative does imply you need a router.

|

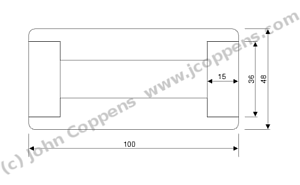

Here's a cut of the strongback, showing how the parts will come

together. Maybe it's possible to do with the cutouts, but these

do contribute a lot to the strength of the strongback.

|

The local EASY sells the plywood in boards of 1.22 by 2.44 meters.

I needed only about half a board, but they only sell entire units.

Ah, well, I'll use what's left to make another sawhorse, which I

needed anyway. EASY has many rules like this... Another one is that

they don't cut narrower strips than 15 cm! This sabotaged my original

idea of taking advantage of their nice cutters to garantee parallel

cuts. The result was a slightly more complicated strategy:

|

Though the original idea was to let them cut all the horizontal strips,

which EASY's rules won't permit, I decided to cut a strip 159 mm wide

which will produce the 4 strips for the top and bottom, and two strips

of 205 mm each, which will provide the sides (100 mm wide).

In each case I calculated a 5 mm margin for each cut, and this

includes the EASY tolerance of 2 mm.

Before cutting the first strip, I had them make a narrow pass with the

machine to get a good initial reference.

|

This is the best way I could figure to use the outer ('good') cuts

for the majority of the following operations. If you use a circular

saw, it may be necessary to foresee more than 5 mm between the strips!

|

I followed the steps as detailed in the sketch. It's not necessary

to pass the router to adjust the outer 100 mm border - it's easier

to assemble the strongback and the plane everything down.

On the drawing, 'Ref' indicates the side I used as a reference

(the side to use the slider of the router on). Also note that it

is advisable to do the last pass of the router with with less 'cut'

to obtain a better quality.

|

|

On the drawing above, two of the narrow strips are marked to be cut at

610 mm, and one of the wider ones at 1220 mm. Doing this, lets me

combine the pieces in such a way none of the unions will coincide

with another one, like this:

I was following the instructions from the book, but, considering

the following experiences, I'm considering that scarping the pieces (instead of just glueing

them butt-to-butt, would have been worthwhile. If I do another

strongback, I will at least scarp the wider strips together!

|

The narrow strips were cut as described in this drawing. It's more

difficult to get all sides really straight, as both internal

strips don't have any original reference.

Maybe it would have been better to use the router to adjust the

strips, but I didn't have a router bit 15 mm high.

|

|

Continues with

pictures of the strongback construction.

|

(c) John Coppens ON6JC/LW3HAZ |

mail |