Bulkheads and hatches

Intro

Well, a couple of weeks ago, we participated, as part of kayaking

classes, of an eskimo roll intruduction. The original S and G

Guillemot, which passed to my wife after I built the strip version,

didn't have bulkheads installed, just a couple of large publicity

bottles, which were more than enough in case of an emergency.

If the sprayskirt doesn't fail, rolls are perfectly feasable in

this state, but, particularly during the learning process,

sprayskirts do fail. Even though the floats will never let the

kayak sink, the amount of water coming in is so large, it gets

quite impossible to manage the boat, and a trip to shore is

necessary.

As the S and G Guillemot was already closed, and access to the places

where the hatches should go is difficult, the system used in hatches as used in the strip built

Guillemot was almost impossible. The selected system, with a

raised hatch, has resulted very effective, though somewhat involved

to construct.

Preparations

Before starting the building process, it's very advisable to make

a sketch on how to solve the problem. Many factors influence the

angles of the sides of the frame: the width of the cut (to remove

the hatch), the angle of the deck, and the thickness of the sealing.

|

This drawing is to determine the inclination necessary, taking into

account the width of the cut, and the thickness of the sealing

strip. First I drew the deck and the (raised) hatch. Then I drew

a couple of wood strips separated with the correct distance for

the sealing strip. I then rotated this last drawing till it

touched both the hatch (outside) and the deck (inside). In the

next section are drawings for different deck angles.

|

|

|

Once glues (with a couple of drops of fast-setting epoxy glue),

I sanded the top and bottom borders to be flush with deck and hatch.

Be careful not to unglue the strips.

|

|

|

Next step is applying glass cloth to reinforce the construction.

I covered the hatch completely, but the deck frame only received a

6cm wide strip. Once the fibreglass has been applied you can

use putty to fill out any spacing between frame and deck/hatch.

|

|

|

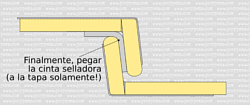

Finally, and after as many hands of sanding, epoxy and varnish as

deemed necessary, you can glue the sealing strip (I used 1.5mm

neoprene) preferably using (water-resistant) contact glue.

|

Specific drawings for the Stitch and Glue Guillemot

Below are a couple of drawing using angles which I measured on

my boat. Yours might be slightly different, though probably near

enough to use the drawings anyway. Of course, if you want to

apply this method for another boat, you're on your own.

|

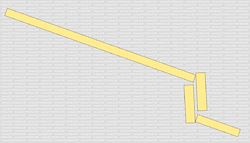

The construction if the deck were perfectly flat. A template made

according to this drawing is useful to align the wood strips of the

front and back of the hatch.

|

|

|

Construction of the sides of the frame, at the aft hatch.

|

|

|

The construction of the front hatch hatch frame.

|

If the work was realized with some care, you'll have hatches that

close quite well. The ones described here survived (actually the

next day) 5 hours of winds of more that 20 knots, and waves over

1 meters (which is quite a lot for our small lake). Not only were

the hatches perfectly sealed, after opening them you could still

appreciate the smell of the last coat of varnish.

Continues with phots of the construction (1)

17000

|

(c) John Coppens ON6JC/LW3HAZ |

mail |